Grinders

Grinders are mainly manufactured in 4 types.

-

Grinders With Seperators:

Grinding process is done with hammers, and the thickness of the grinding is controlled with the seperator over the grinder. In order to activate the system vantilator, cyclones, grinded materials stocks, filter and piping is also neeeded. This grinder is mostly suitable for any kind of mineral and mine.

-

Tpo Type Standart Grinders:

Grinding process is made with hammers or pallets. Thickness of the grinding is controlled with the sieve on the exit of the grinder. This grinder is an universal one and is suitable for food materials. The material to be grinded in this ne should not be more than 8 mm. Power is 1,5 kw.

The materials that can be grinded in this grinder are:

- Sugar

- Cereal

- Dry Foods

- Salt

- Mines

- Minerals

-

Tpo Type Grinders With Needles:

Grinding is done with the needles on the rotar and stator. The factors affecting the grinding thickness are;

- The size of the material

- The fragility of the material

- The rpm of the rotar

- The number of the needles

- The humidity of the material

- This grinder is especially used for grinding the material into micron values.

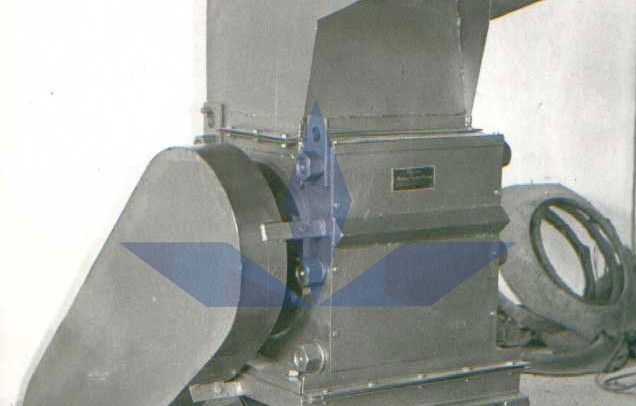

Grinders With Knives:

Grinding is done by knives with cutting. Thickness of the grinding is controlled with the sieve on the exit of the grinder. This grinder is used for elastic materials, especially like linter, paper and thin plastic plates.